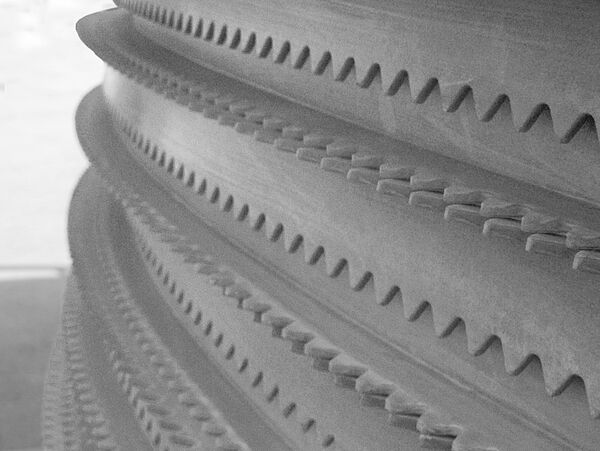

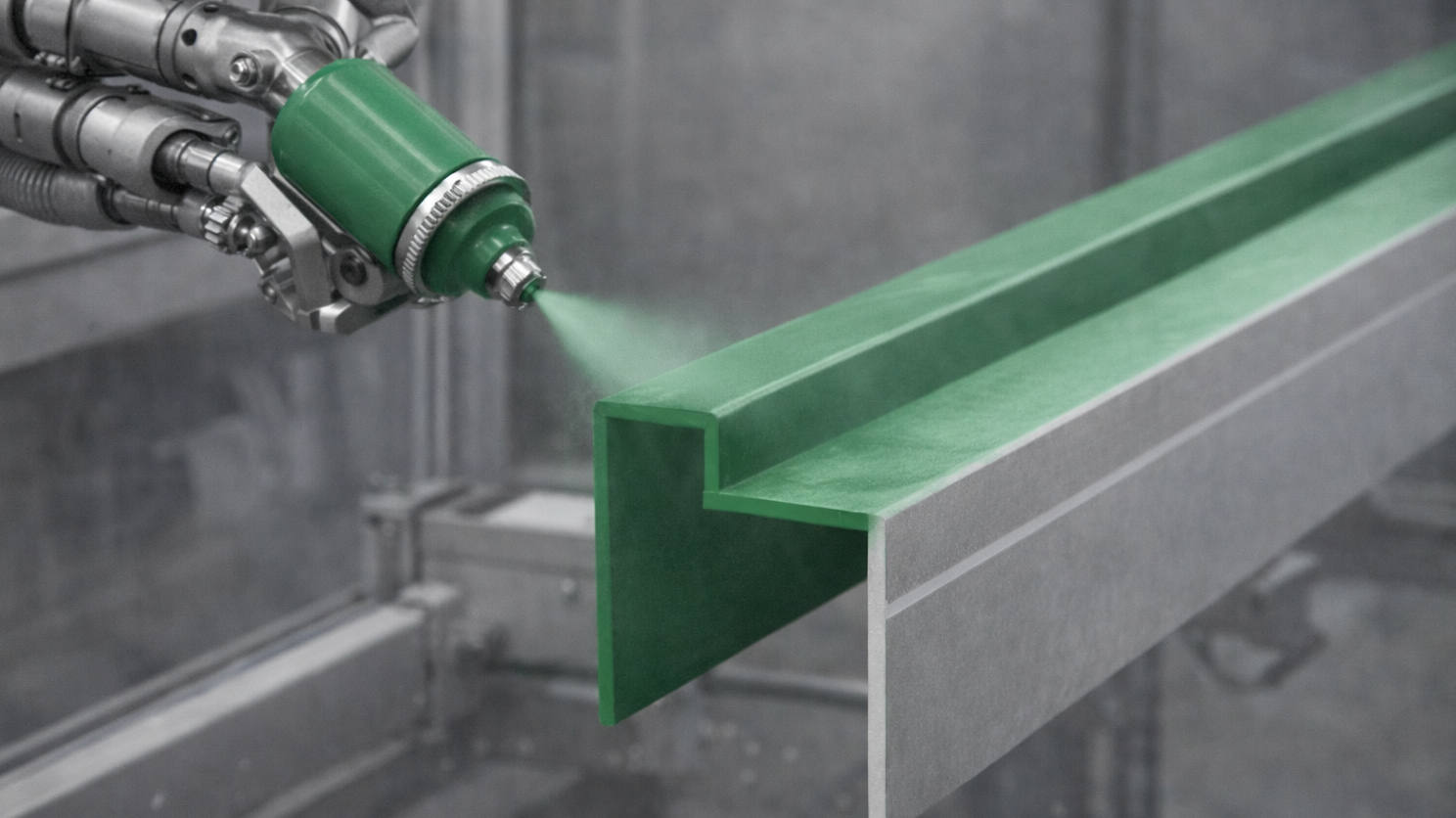

We provide custom mechanical processing of GRP profiles according to your individual specifications. Using CNC-controlled machines, we carry out precise operations such as cutting, drilling, milling and other machining steps.

All processing is performed with high dimensional accuracy, tailored to dimensions, wall thicknesses and the intended application. Our team ensures that GRP profiles and grating panels are properly prepared for further processing or installation.