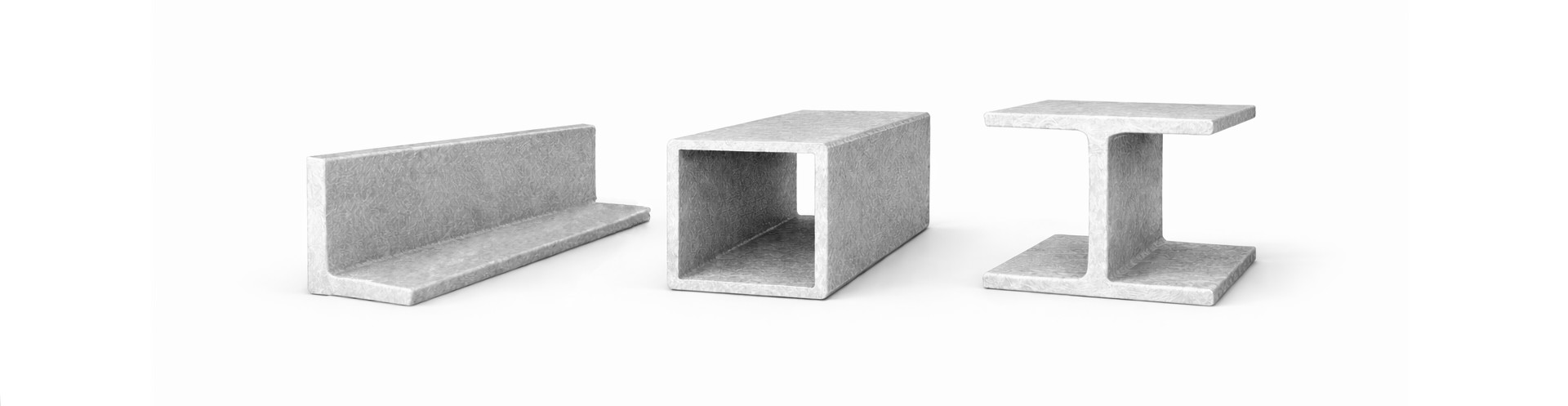

GRP PROFILES

Our GRP profiles made from glass fibre–reinforced composites, manufactured in Europe, are distinguished by their durability and high corrosion resistance and represent a cost-effective alternative to conventional materials such as concrete, wood, stainless steel, and aluminium.

The diverse areas of application for our GRP profiles cover a wide range of sectors and industries. Whether offshore applications, railway systems, the chemical industry or other infrastructure facilities – our profiles offer flexible solutions for complex challenges.

Fibrolux – GRP profiles

Discover our comprehensive range of GRP profiles, which have been specially developed for a wide range of applications and industries. Take a look at the different options and find the perfect profile for your needs.

Do you have any questions about our GRP profiles?

What are the advantages of GRP profiles?

GRP profiles (glass-fibre-reinforced plastic profiles) offer a number of advantages that make them particularly attractive for various industrial and commercial applications. Here are some of the most significant advantages:

- High strength and durability: GRP profiles are known for their high tensile, bending and impact strength, making them a robust choice for demanding environments.

- Corrosion resistance:These profiles are resistant to many chemicals and corrosive environments and are therefore ideal for use in chemical factories, sewage treatment plants and coastal regions.

- Low weight:GRP profiles are much lighter than comparable metal structures, such as steel or aluminium, making them easier to handle, transport and install.

- Good insulating properties:GRP provides natural insulation against heat and electricity, making it useful for electrical and thermal applications.

- Weather resistance:GRP profiles are UV and weather resistant, making them ideal for outdoor applications where durability is required under extreme weather conditions.

- Adaptability:GRP production processes enable the production of profiles in various shapes and sizes, increasing flexibility in design and making it easier to meet specific requirements.

- Low maintenance:They require less maintenance than metal structures because they do not rust or rot and do not need to be painted or sealed regularly.

What is meant by GRP?

GRP, short for glass-fibre-reinforced plastic, is a composite material consisting of a plastic matrix with embedded glass fibres. This combination gives GRP a high degree of strength and durability alongside a low weight and excellent corrosion resistance at the same time.

The plastic – often a polyester, epoxy or vinyl resin – binds the glass fibres, which increase the mechanical strength. Due to its versatile properties, GRP is used in a variety of industries.

What is a GRP profile?

GRP profiles are components made of glass-fibre-reinforced plastic, a composite material known for its high strength and low weight. These profiles are made by combining synthetic resin with glass fibres, giving them excellent resistance to corrosion, weathering and chemical substances.

Due to these properties, GRP profiles are widely used in various industries, such as construction, the automotive industry and electrical engineering, where conventional materials such as steel or aluminium are not ideal. They are particularly useful in environments where robustness is required without additional weight.

CONTACT US WITHOUT OBLIGATION!

Do you have any questions about our products or the various application options? We will be happy to advise you!