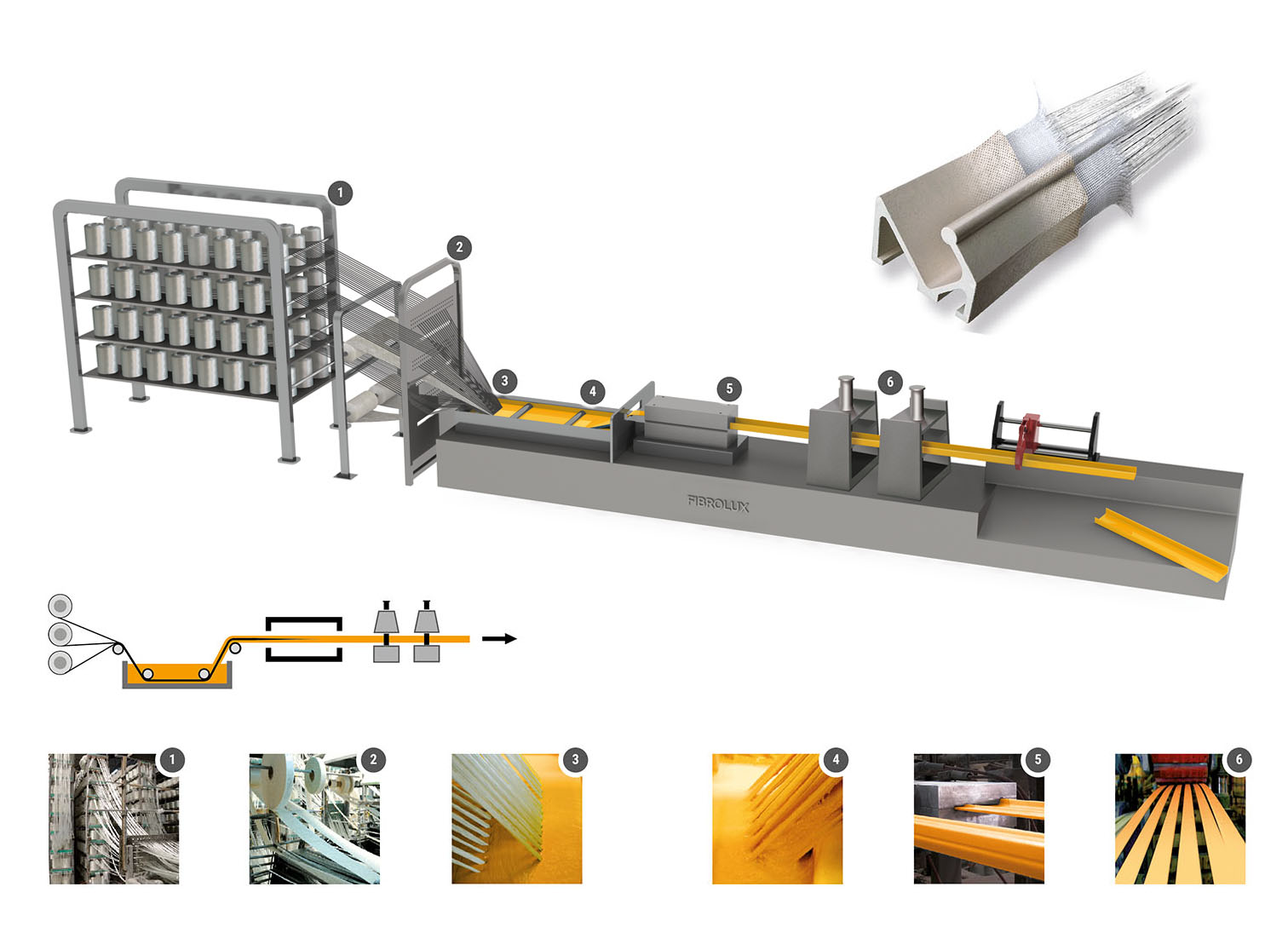

PULTRUSION

The pultrusion process is a method of producing glass-fiber-reinforced plastic profiles with a constant cross-section in a continuous process. In this process, multiple reinforcing fibers are drawn through a resin bath into a temperature-controlled, heated metal mold. As a result, structural profiles with different shapes can be produced.

In order to improve the mechanical properties in the longitudinal direction, pultruded components are made on the one hand from direct rovings and on the other hand also from texturized rovings to fill the angles better. Continuous fiber mats and fabrics provide improved mechanical properties in the transverse direction. Surface nonwovens improve the surface quality of the component