Characteristic values

Depending on the type of fiber reinforcement of the profile structure and the wall thickness, the technical data of the GRP profiles vary. The application-specific suitability must be checked in each individual case.

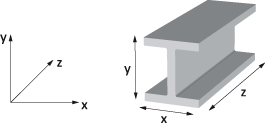

| GRP profile type MR Mat/Roving-reinforced | GRP profile type UD Roving reinforced |

||

|---|---|---|---|

| Z | X | Z |

|

| Tensile strength | 250 - 450 MPa | 20 - 60 MPa | 900 MPa |

| Flexural strength | 250 - 450 MPa | 20 - 60 MPa | 900 MPa |

| E-modulus (tensile strength) | 25.000 MPa | 9.000 MPa | 40.000 MPa |

| E-modulus (bending) | 25.000 MPa | 9.000 MPa | 40.000 MPa |

| Elongation at break | 1,0 - 1,8 % | 2 % | |

| Compressive strength | 150 - 300 MPa | 30 - 60 MPa | 450 MPa |

| Compressive modulus | 10.000 MPa | 4.000 MPa | 30.000 MPa |

| Density | 2,0 kg/dm³ | 2,1 kg/dm³ | |

| Impact strength IZOD | 90 - 120 kJ/m² | 120 kJ/m² | |

| Barcol hardness | > 40 | > 50 |

| Characteristic values applicable to all types | |

|---|---|

| Interlaminar shear strength | 25 - 35 MPa |

| Specific volume resistivity | 10^10 - 10^15 Ohm* cm |

| Surface resistance | 10^10 - 10^15 Ohm |

| Dielectric strength | 5 - 10 kV/mm |

| Tracking resistance CTI | KA 3c / KB 500 / KC 600 |

| Dielectric constant | < 5 |

| Lin. Coefficient of thermal expansion | 12 x 10 -61/K |

| Thermal conductivity | 0,2 - 0,6 W/m*K |

| Spec. heat capacity | 1,0 - 1,2 kJ/kg*K |

| Continuous operating temperature | -100°C bis +155°C (180°C) |

| Water absorption | < 0,15% |

| Dimensional stability n. Martens | 200°C |

| Ember resistance | Level 2b |

| Fire behaviour | B2, UL94 V1, UL94 V0, DIN 5510 S4 SR2 ST2, ASTM E84 < 25, ASTM D635 |

Application limits

| Short-term behaviour | Long-term behaviour | |||

|---|---|---|---|---|

| Type MR | Z | X | Z | X |

| Bending stress | 135 MPa | 20 MPa | 70 MPa | 15 MPa |

| Tensile stress | 135 MPa | 20 MPa | 70 MPa | 15 MPa |

| Compressive stress | 135 MPa | 25 MPa | 70 MPa | 20 MPa |

| Shear stress Z=X | 25.000 MPa | 8 MPa | ||